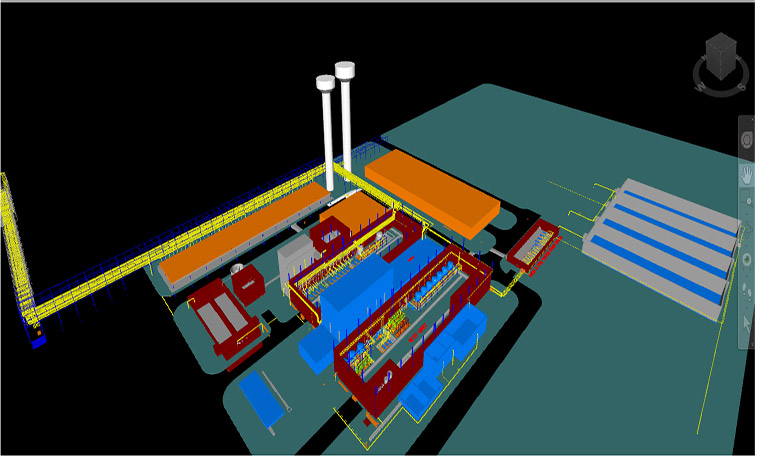

∗ Capacity: 78120 cubic meters per day

∗ Location: Middle East

∗ Key Project Features:

000♦ Engineering Services by MGET Manager

∗ Commencement: 2019

∗ Status: Finished

Project description:

Raw water flows to water treatment unit with TDS and ferric iron up to 1300 ppm and 0.3 ppm, respectively. Also, industrial wastewater which circulate in contact circuit cooling tower loop returns back to wastewater treatment unit with TSS and oil content of 400 ppm and 15 ppm, respectively. In general, plant consists of following equipment:

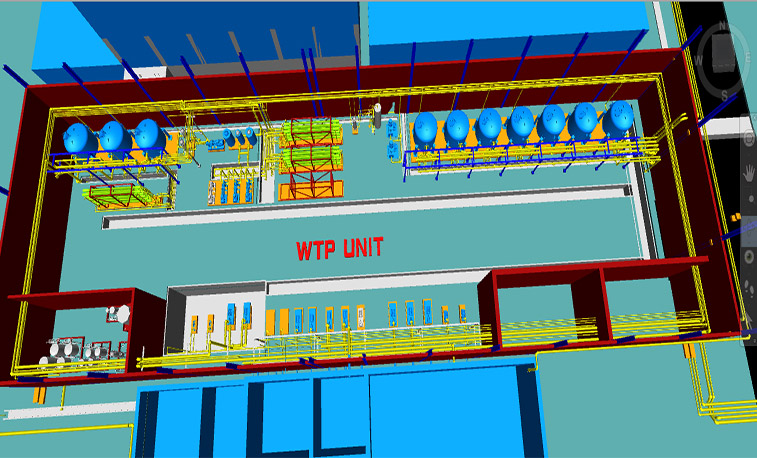

Water treatment unit

000♦ WTP sand filters

000♦ RO train

000♦ CO2 degasser

000♦ Demineralized column and neutralization

000♦ Potable water sand filter

000♦ Elevated water tank

000♦ Firefighting system

Reuse unit

000♦ Equalization tank

000♦ Reuse Filters

000♦ RO train

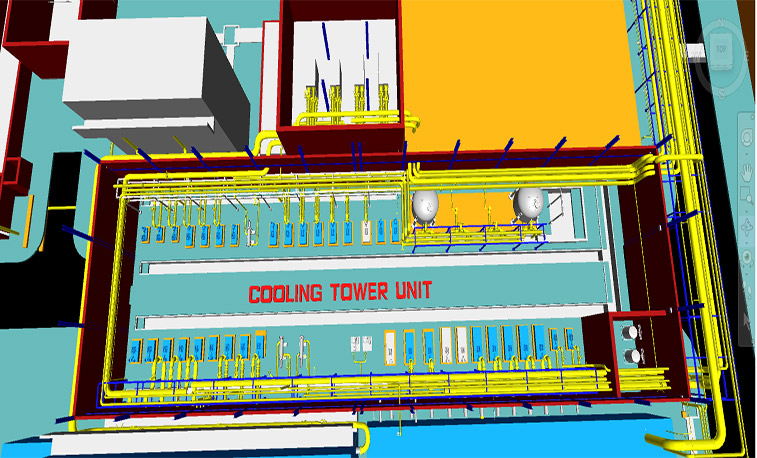

Cooling water unit

000♦ Open indirect circuit cooling tower

000♦ Contact circuit cooling tower

000♦ Heat exchanger

000♦ Self-cleaning filter

Air cooler unit

000♦ Air cooler

000♦ Self-cleaning filter

000♦ Emergency Tower

Industrial wastewater treatment unit

000♦ Settling basin

000♦ Sand filters

000♦ Thickener

000♦ Filter press

Highlights:

The most challengeable part of this plant was as following:

000♦ Removal of ferric iron from feed water to RO unit

000♦ Achieving Maximum Recovery of Reuse unit